close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

Product Description

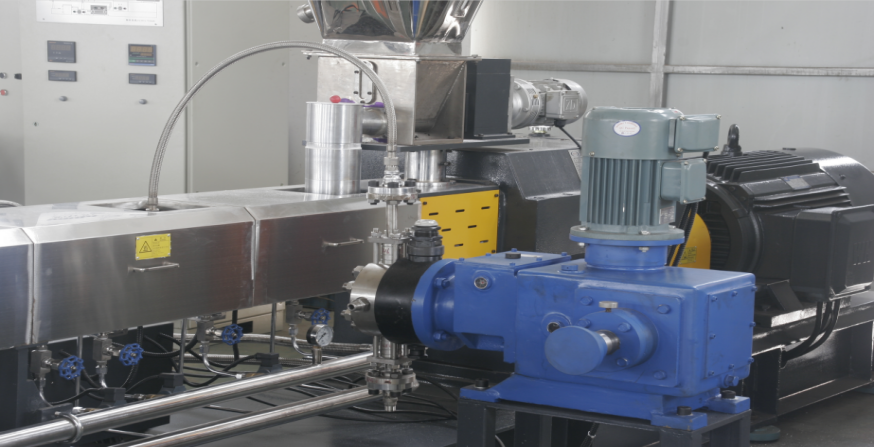

Depending on the production capacity, you can choose your own extruder. Starsplas now produces two models, the 115 and 130 extruder. Extruder and T die extrusion SPC/PVC base material, respectively with three or four roller calendering machine, SPC/PVC wear-resistant layer, SPC/PVC color film and SPC/PVC base material, one-time heating and laminating, embossing products, the process is simple, close to heating can be completed, do not need glue.

1. Screw design has special mixing function, strong plasticizing ability, which ensures the plastic melting, coloring uniformity and high yield.

2. Hanger die head adopts double throttling design to adjust sheet thickness more accurately.

3. The temperature control precision of ±1℃ can accurately control the plasticizing process, thickness and surface finish of the sheet.

4. Roller arrangement can be vertical, horizontal or free adjustment, according to different plate thickness to provide more choices.

5. Screw adjustment and oil roller bidirectional adjustment, can accurately control the thickness of the plate.

| Model number | TYΦ115/28 | TYΦ130/28 | ||||||||

| Screw diameter (mm) | Φ115 | Φ130 | ||||||||

| Length-diameter ratio | 28:1 | 28:1 | ||||||||

| Screw speed (r/min) | 5-31 | 5-31 | ||||||||

| Maximum capacity (kg/h) | 900 | 1200 | ||||||||

| Product width (mm) | 970-1270 | 970-1270 | ||||||||

| Product thickness (mm) | 3-8 | 3-8 | ||||||||

| Main motor power (kw) | 75 | 110 | ||||||||

SPC Vinyl floor board /SPC Floor board /pvc floor tile /pvc floor board/luxury vinyl floor board/Waterproof vinyl floor board/Interlocking pvc floor tile covering produced by SPC Floor vinyl Board Extruders SPC floor board manufacturing machines are widely used in many different lines for a variety of applications, including: Department stores, hotels, hospitals, restaurants, banks, offices, homes.

Q&A

1. What is the difference between flat twin extruders and cone twin extruders?

Flat twin screw extruder and cone twin screw extruder are two common types of extruder, and there are the following differences between them: ① The structure is different: the screw of flat twin screw extruder is arranged in parallel, and the screw of cone twin screw extruder is arranged in conical shape. ② Different feeding methods: the feed port of flat twin screw extruder is usually on the top of the extruder, while the feed port of cone twin screw extruder is on the side of the extruder. ③ Different range of application: flat twin screw extruder is suitable for dealing with high viscosity, high molecular weight materials, and cone twin screw extruder is suitable for dealing with low viscosity, low molecular weight materials. ④Different discharge methods: flat twin screw extruders usually use panel die for extrusion molding, while cone twin screw extruders usually use cylindrical die for extrusion molding. In general, there are obvious differences between flat twin screw extruder and cone twin screw extruder in structure, feeding mode, application scope and discharging mode, so it is necessary to choose the appropriate extruder number according to the specific processing requirements.

2. What is the output of the flat twin extruder?

Starsplas sells flat twin extruders in two models: the 130 and the 160. The production capacity of the 130 model extruder is 38-40 tons per day, and the floor volume can be about 4500m2 per day. 160 model extruder has a daily production capacity of 50-60 tons, and can produce floor volume of about 7000m2 per day.

Contact information

WhatsApp:+86 19962650268

TEL:+86 19962650268

Wechat:+86 19962650268

Mail:eve@starsplas.com

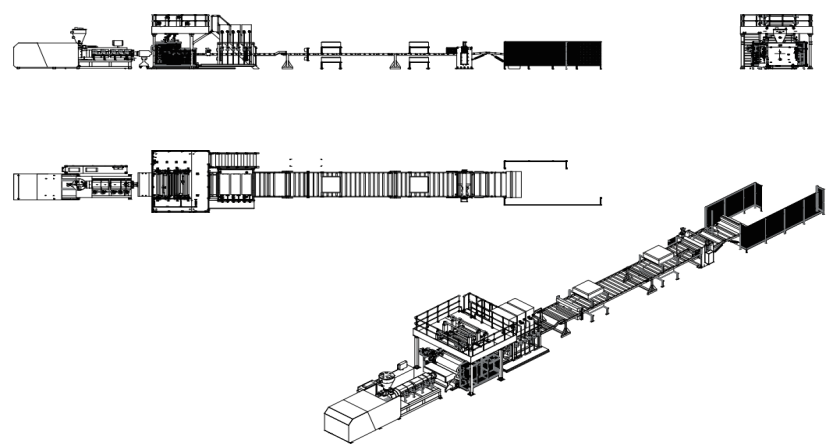

Product display drawing