close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

Plastic waste is a growing concern worldwide, but what if we could recycle it efficiently? One solution is using an HDPE Bottle Washing Line. This technology helps reduce waste, save costs, and improve material quality. In this article, we'll explore how integrating an HDPE Bottle Washing Line can benefit manufacturers, improve sustainability, and streamline production.

HDPE, or High-Density Polyethylene, is a versatile plastic material used in a wide range of everyday products, from milk jugs to shampoo bottles. Known for its strength, resistance to impact, and chemical durability, HDPE is a preferred material for packaging due to its low permeability to water, oils, and chemicals. HDPE bottles are widely used in industries such as food, beverages, and personal care products. However, the increased usage of HDPE also brings the challenge of efficiently managing waste, making recycling an essential solution. HDPE Bottle Washing Lines provide an efficient way to process post-consumer HDPE bottles, transforming them into valuable resources for further manufacturing. The table below highlights key properties of HDPE and its application areas, helping to understand its importance in manufacturing.

| Property | Description | Application Areas | Technical Specifications |

|---|---|---|---|

| Chemical Resistance | Excellent resistance to acids, alkalis, and salts | Food packaging, chemical containers | Resistance to chemicals: strong acids, strong bases |

| Strength | High tensile strength, impact resistance | Milk bottles, shampoo bottles | Tensile strength: ≥30 MPa |

| Environmental Stress Cracking | Good resistance to environmental stress cracking | Transport, storage containers | Environmental stress cracking: None |

| Processability | Easy to process and mold | Plastic bags, pipes | Melt flow index: 0.2 - 0.5 g/10 min |

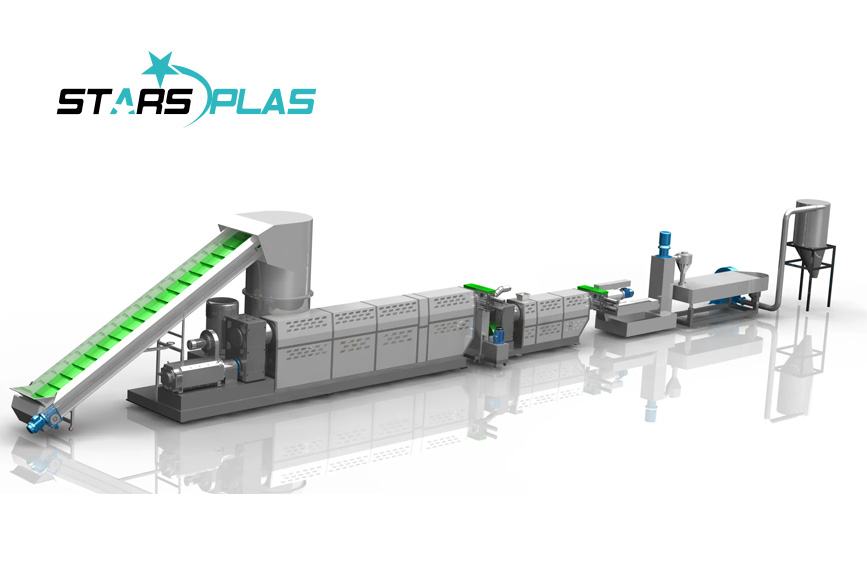

An HDPE Bottle Washing Line consists of several key components that work together to process and clean the plastic. These typically include shredders, washers, friction cleaning units, drying systems, and optional separation tanks. The process begins with the collection and pre-sorting of used HDPE bottles. Next, the bottles are shredded into smaller pieces, which are then cleaned using high-speed friction washers. The contaminants, such as labels, adhesives, and dirt, are effectively removed during this stage. Finally, the washed HDPE flakes are dried to prepare them for reuse in manufacturing processes.

The operation of an HDPE Bottle Washing Line follows a systematic process designed for maximum efficiency and quality. It starts with pre-sorting, where contaminants are removed, followed by wet crushing, where bottles are reduced into smaller flakes. These flakes are then subjected to friction washing, which uses high-speed scrubbing to remove stubborn contaminants. Afterward, the HDPE flakes go through a sink-float separation system to ensure purity by separating them from heavier materials like PET or PVC. The final step in the process is drying, which reduces moisture content to below 3%, ensuring the clean, dry flakes are ready for the next stage of production.

By using an HDPE Bottle Washing Line, manufacturers can significantly reduce production costs. The process of recycling post-consumer HDPE bottles into reusable rHDPE flakes reduces the need for purchasing virgin plastic materials, which can be expensive. Additionally, recycling HDPE in-house can save on disposal fees and landfill costs. With the ability to reuse the same material, manufacturers can reduce their reliance on external suppliers, cutting down on material costs in the long term. By switching to recycled HDPE, companies also experience a decrease in raw material expenses, leading to more competitive pricing for their products.

The table below demonstrates the cost savings when using recycled materials compared to using virgin plastics, helping manufacturers understand the economic benefits of investing in a washing line.

| Cost Item | Using Recycled HDPE | Using Virgin HDPE | Savings Percentage |

|---|---|---|---|

| Raw Material Costs | Recycled HDPE is cheaper | Virgin plastic is more expensive | 20%-30% savings |

| Waste Disposal Fees | In-house recycling reduces transportation and landfill costs | External waste disposal is more expensive | 40%-50% savings |

| Energy Consumption | Energy-efficient equipment, high recycling rate | New plastic production requires high energy | 30%-40% savings |

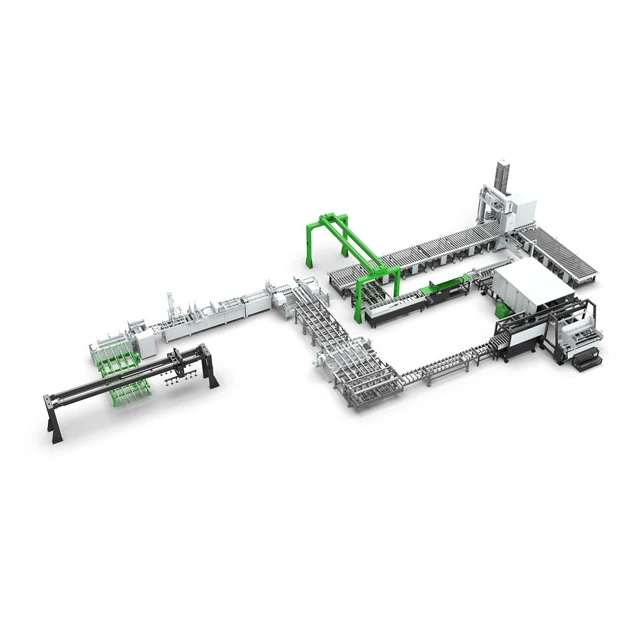

HDPE Bottle Washing Lines are highly automated, minimizing the need for manual labor and streamlining the entire recycling process. The automation allows manufacturers to handle large volumes of HDPE bottles with fewer resources, which results in higher throughput and reduced labor costs. Automated sorting and cleaning systems ensure consistent product quality and efficiency, improving overall manufacturing speed. The reduction in manual labor also minimizes human errors, further enhancing operational efficiency. With features like PLC and HMI control systems, these washing lines allow for remote monitoring, ensuring smooth operation with minimal interruptions.

The HDPE Bottle Washing Line's advanced cleaning processes result in high-quality rHDPE flakes that meet industry standards. The multi-stage washing process, including friction washing and sink-float separation, ensures that impurities such as adhesives, glues, oils, and food residues are thoroughly removed. This leads to high-purity rHDPE flakes that are suitable for a variety of manufacturing applications. The drying systems further enhance quality by ensuring that moisture levels are kept low, preventing any issues during downstream pelletizing or extrusion. The resulting flakes are ready for high-quality product manufacturing, whether it's for new bottles, pipes, or other industrial applications.

HDPE Bottle Washing Lines play a crucial role in reducing plastic waste by recycling post-consumer HDPE bottles. Instead of these bottles ending up in landfills or oceans, they are processed and turned into valuable rHDPE material that can be reused in new products. This recycling process helps divert large quantities of plastic waste from contributing to environmental pollution. By transforming waste into resources, HDPE washing lines contribute to solving the global plastic waste problem, helping manufacturers play a key role in protecting the environment.

Recycling HDPE bottles requires significantly less energy than producing virgin HDPE. The recycling process consumes fewer resources and generates lower carbon emissions, contributing to a smaller environmental footprint. By using recycled rHDPE instead of virgin plastic, manufacturers can help reduce the overall energy consumption associated with plastic production. This reduction in energy usage not only lowers operational costs but also supports the global push for sustainability and reducing greenhouse gas emissions.

HDPE Bottle Washing Lines contribute to the concept of the circular economy, which aims to close the loop on material usage by ensuring that products are reused, repaired, and recycled. Rather than relying on virgin plastic, which requires the extraction of petroleum and significant energy input, recycled HDPE can be used to create new products, reducing the need for raw materials. This practice helps conserve natural resources and supports the development of more sustainable manufacturing processes. By adopting HDPE washing lines, companies are actively contributing to the creation of a circular economy.

Recycled HDPE is a cost-effective alternative to virgin plastic materials. Manufacturers can purchase rHDPE flakes at a lower cost than virgin HDPE, which is subject to fluctuating prices due to the volatility of raw material markets. By using recycled HDPE, manufacturers can stabilize their raw material costs and achieve better control over their production expenses. This results in long-term cost savings and improved profitability. Moreover, the availability of a constant supply of recycled materials ensures that manufacturers can maintain production even during market disruptions in the plastic industry.

The initial investment in an HDPE Bottle Washing Line can provide significant long-term returns. Over time, the reduced reliance on external plastic suppliers, coupled with savings on waste disposal, contributes to higher profitability. The ability to produce high-quality rHDPE flakes for a variety of applications also opens up additional revenue streams, as recycled materials are in high demand across industries. The market for eco-friendly products and packaging continues to grow, and by adopting HDPE recycling systems, manufacturers can position themselves as leaders in sustainable production, giving them a competitive edge.

As consumer demand for environmentally friendly products continues to rise, manufacturers who invest in HDPE Bottle Washing Lines can enhance their brand image and reputation. Companies that incorporate recycled HDPE into their products demonstrate a commitment to sustainability, which can attract environmentally conscious customers. Additionally, many governments and industries are implementing regulations that require recycled content in packaging. By using rHDPE, companies can comply with these regulations while meeting consumer expectations, making them more appealing to both consumers and business partners.

Many countries around the world have strict regulations governing the use of recycled materials in packaging, including HDPE. HDPE Bottle Washing Lines help manufacturers comply with these regulations by ensuring that the recycled material meets quality standards required for various applications. Whether it is for food packaging, consumer goods, or industrial products, the quality of rHDPE produced through these washing lines adheres to international standards, making it easier for companies to meet regulatory requirements.

Consumers are increasingly concerned about the environmental impact of the products they purchase. There is a growing expectation that companies adopt sustainable practices, such as using recycled materials in their packaging. By investing in an HDPE Bottle Washing Line, manufacturers can respond to this demand by offering products made from recycled HDPE. This commitment to sustainability not only meets consumer expectations but also strengthens brand loyalty, as customers are more likely to support businesses that prioritize the environment.

Brands that adopt sustainable practices stand out in today’s competitive marketplace. Companies using HDPE Bottle Washing Lines to recycle plastic waste and reduce their environmental impact can improve their reputation as environmentally responsible manufacturers. This positive image can attract more customers, increase market share, and foster goodwill among consumers and stakeholders. Additionally, companies that prioritize sustainability often gain recognition from industry groups, government agencies, and environmental organizations, further boosting their brand’s reputation.

Recycled HDPE (rHDPE) is widely used in creating new products across various industries. The following table outlines the applications of rHDPE, its key technical specifications, and best practices for manufacturers utilizing recycled HDPE in their products.

| Product Type | Application Areas | Key Benefits | Technical Specifications | Considerations |

|---|---|---|---|---|

| Packaging Materials | Bottles, containers, plastic bags | High strength, impact resistance, eco-friendly | Tensile strength: ≥30 MPa | Ensure compliance with food safety regulations for food-grade packaging |

| Plastic Lumber | Construction, landscaping, outdoor furniture | Weather-resistant, UV-resistant, durable | UV resistance: ≥10 years, moisture absorption: <3% | Suitable for outdoor environments, consider structural integrity |

| Pipes | Plumbing, drainage systems | Corrosion-resistant, long-lasting | Burst pressure: ≥150 PSI, diameter: 4-12 inches | Use in non-potable water systems, ensure proper sealing |

| Automotive Parts | Interior components, bumpers, dashboards | Lightweight, impact-resistant, recyclable | Impact resistance: ≥80 Joules, weight: <2 kg | Ensure compatibility with automotive standards and certifications |

| Industrial Goods | Electrical housings, agricultural films | Durable, chemical-resistant, versatile | Chemical resistance: ASTM D1693 | Suitable for specific industrial applications, check compatibility with chemicals |

Tip: When using rHDPE for manufacturing new products, always ensure it meets the specific regulatory and quality standards of the relevant industry to maintain product performance and compliance.

Recycled HDPE is used in various sectors, including packaging, construction, and automotive industries. In packaging, it is used to produce new bottles and containers, while in construction, it can be used for plastic lumber, water pipes, and other infrastructure materials. The automotive industry also uses rHDPE for parts such as bumpers and dashboards. This versatility makes HDPE recycling an attractive option for businesses across multiple sectors looking to incorporate sustainable practices into their supply chains.

The quality of rHDPE produced by an HDPE Bottle Washing Line is crucial to its application in different industries. The cleaning and separation processes ensure that the final product meets the high standards required for various uses. Whether it's food-grade packaging or durable construction materials, the purity and consistency of rHDPE ensure that it meets industry specifications. This makes it an ideal material for manufacturers looking to comply with regulations and produce high-quality products.

Incorporating an HDPE Bottle Washing Line into manufacturing processes offers numerous benefits. It reduces plastic waste, enhances operational efficiency, and promotes environmental sustainability. By recycling post-consumer HDPE bottles, these lines help lower carbon footprints and support the circular economy. Companies like Stars Union Equipment Technology (jiangsu) Co., Ltd. provide advanced HDPE washing technology, enabling manufacturers to improve production efficiency, meet regulatory standards, and strengthen brand reputation. As sustainability grows in importance, investing in HDPE Bottle Washing Lines is crucial for a more sustainable manufacturing future.

A: An HDPE Bottle Washing Line is a system used to recycle post-consumer HDPE bottles. It cleans and processes bottles, removing contaminants, and turns them into reusable rHDPE material for manufacturing new products.

A: The HDPE Bottle Washing Line works by shredding HDPE bottles, washing them using high-speed friction washers, separating contaminants, and drying the material to produce clean rHDPE flakes ready for reuse in manufacturing.

A: Investing in an HDPE Bottle Washing Line helps manufacturers reduce plastic waste, lower raw material costs, improve operational efficiency, and meet sustainability goals by recycling post-consumer HDPE bottles into valuable resources.

A: The cost of an HDPE Bottle Washing Recycling Line can vary depending on the size and features, but it typically provides long-term savings by reducing raw material costs and minimizing waste disposal fees.

A: The benefits of using an HDPE Bottle Washing Line include cost savings, enhanced production efficiency, reduced environmental impact, and the ability to produce high-quality rHDPE for various industries.

A: The HDPE Bottle Washing Line promotes sustainability by recycling HDPE bottles, reducing plastic waste in landfills and oceans, and supporting the circular economy by transforming waste into valuable materials.

HDPE Bottle Washing Line for Recycling: Efficiency And Sustainability

The Benefits of Using An HDPE Bottle Washing Line in Manufacturing

How HDPE Bottle Washing Lines Improve Product Quality And Safety

Plastic Shredder: Understanding Its Mechanism And Efficiency

How Plastic Shredders Transform Waste into Reusable Material